Our approach to Quality Management ensures that we’re always speaking the same language.

When it comes to needing a Quality Management Solution, there are numerous benefits to working with a CDMO like Veranex. We have the flexibility to adapt to the client’s needs whether that’s operating under their QMS or using our own. We have core infrastructure such as two ne class 10,000/ISO 7 and one class 100,000/ISO8) complete with a full environmental monitoring system, badge access controls, and inventory control ready to go. At Veranex, we maintain a robust Quality Management system with established procedures, proven validation processes, . Plus, our experts are adept at “speaking the same language” when it comes to having conversations about change/control. Read on to hear about the top five advantages to choosing Veranex for your product design or contract manufacturing projects.

1) Industry Expertise

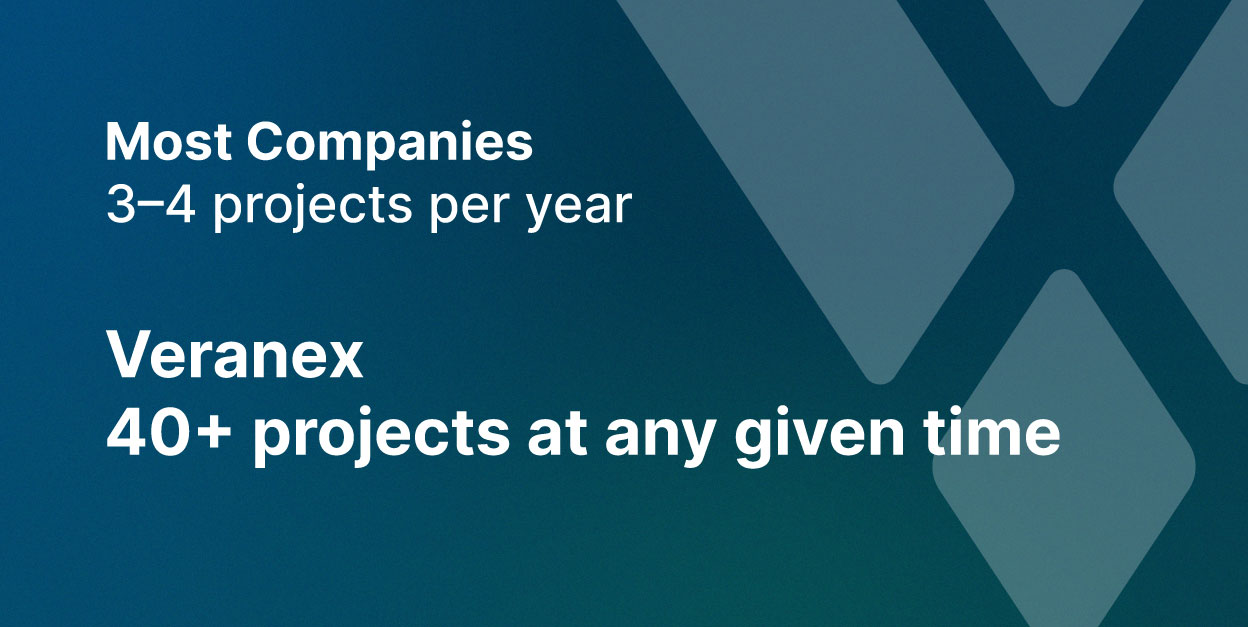

At other companies, repetitions in terms of paperwork and process can be few and far between. Design centers are separate from manufacturing facilities which adds to the siloed nature. Due to the nature of our business and the way our teams are integrated, we do things at a higher frequency which means we’re comfortable with aspects of QMS that only happen sporadically at other companies. What feels like a marathon for another company is our 5K.

While QMSs have been around for medical device companies for many years, there’s a lack of standardization in terms of variations of QMS being used and advancements being adopted. We deal with clients across the spectrum. We recognize that not every company has the resources to advance new technology within their QMS or because they may work within a singular process. That’s why our QMS is driven by each client’s specific needs — our deep experience working with clients across all levels of expertise and capabilities.

2) Adaptability

Our team offers tailored guidance and recommendations based on our experience with all different types of devices in a wide range of therapeutic areas. Our procedures are agnostic to what you’re trying to make, meaning we can do anything from in-vitro diagnostics to single-use disposable auto-injector pens with drugs, to large capital equipment. We also take into consideration a client’s appetite for risk — adapting to whatever that appetite is. We understand the different levels of risk and can take a route that meets the client’s goals. These are decisions that can help lower costs, shorten timelines, and get a device to market faster. Finally, our team is used to going on-site to help develop processes or manage a project and are well-versed in learning the client’s QMS to develop procedures that function within that environment.

3) Scalability

Getting audited by the FDA and obtaining ISO-13485 certification is an arduous process that is necessary to get to the starting line of commercialization. The cost to develop, implement and support compliance can be overwhelming. Having the ability to understand our clients’ needs allows us to pick up a project at any point in the process and support all the way through commercial production. Whether you’re a start-up, large strategic, or somewhere in the middle, this is helpful to you. There’s no size company that doesn’t benefit from our services.

4) Robust Infrastructure

Much like our experience with constant repetition in terms of process, we also get audited a lot. Our clients audit as part of their approval process and we consistently pass those audits with zero issues to report. We are committed to investing in our QMS through continuous improvements, the expansion of our electronic systems and systems integrations to ensure a streamlined, efficient approach to manufacturing. All of this requires a wealth of knowledge and process expertise to get the job done, which results in greater efficiency and less risk for our clients.

5) Data Analytics

The benefit of working with a CDMO like Veranex is that we have all of the data under one roof, which allows us to leverage it to improve design inputs for manufacturing and next-generation development. We have the ability to see trends and find problems within milestones — it’s a closed feedback loop. We can see something that needs to be improved in a trend format versus one single data point and course-correct our procedures to lower some identified risk. What gets fed into our process gives us a unique snapshot compared to what other companies offer. We’re always working to improve our project management process, our client development process, our pipeline, our invoicing process and our overall customer service experience for clients.