BIOCOMPATIBILITY

Developing a Biological Risk Assessment Strategy for Portfolios of Medical Devices

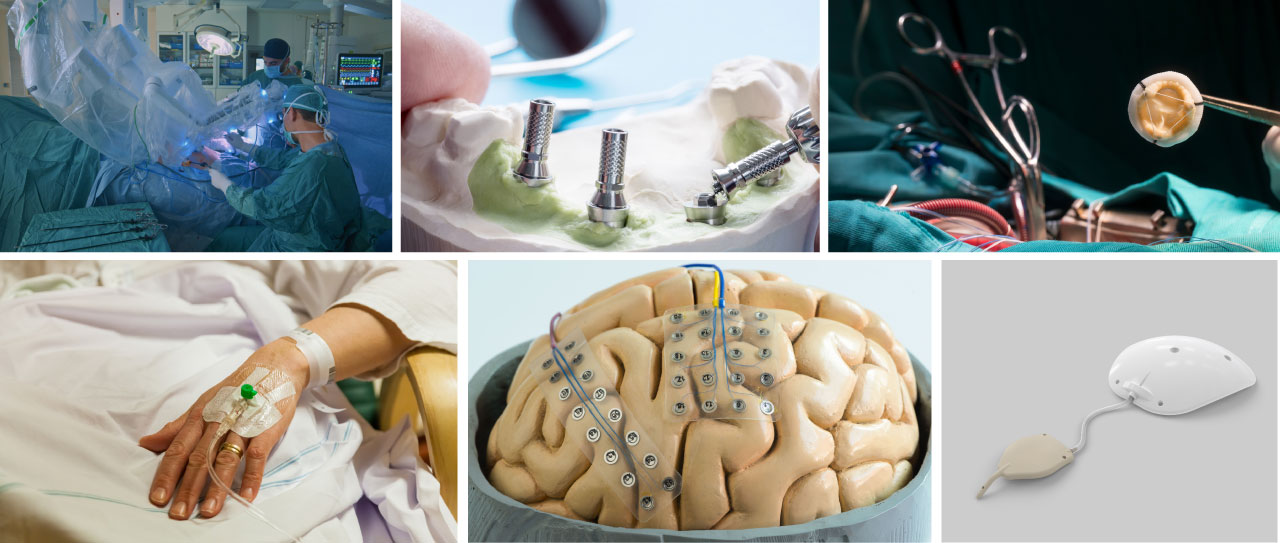

Veranex provides continuous expert support for the assessment of the biological safety of external devices, surgical tools, implants, substance-based products, and more.

Services

Industry

The Challenge

For many medical device manufacturers, the transition from Medical Device Directive 93/42/EEC (MDD) to Medical Device Regulation 2017/745 (MDR) triggered a need to review technical documentation — specifically, the evaluation of biological safety due to its scrutiny by Notified Bodies. In the US, biocompatibility is also a topic the FDA pays particularly attention to.

Our clients often need support to ensure that Notified Bodies’ and FDA expectations are met — requiring detailed risk analyses and scientific rationales to substantiate the biological safety of medical devices. This can be challenging for high-risk products but also when assessments are made for large portfolios of products, requiring continued and consistent support from a team of experts.

The Solution

The biological safety expert team at Veranex provides continuous support for updating Biological Risk Assessments (BRAs), ensuring validity of existing tests, and, as required, planning additional tests and analyzing the results.

In some cases, per the client’s request, the support starts with an update to the client’s internal biological safety process (SOP) and template for the redaction of BRAs. In other cases, Veranex uses their internal processes and templates.

Then, to optimize efficiency, a team is assembled at Veranex to include specific competences according to the needs (regulatory, toxicology, analytical chemistry, biology, material science, nanomaterials…). This allows Veranex to “think out of the box” and answer non-trivial questions the clients sometimes receive from Notified Bodies and the FDA during the review process.

This team is able to assess the biological safety of various products, from single high-risk devices to large portfolios of devices. For several clients, over the course of a support that may last over several years, tens of products were assessed (dental products, dressings, intravenous catheters…). For large portfolios, consistently delivering highly detailed accurate scientifically-backed risk assessments is key to ensure a smooth MDD to MDR transition or to pass the scrutiny of a FDA review.

Veranex also provides the necessary training on biocompatibility to ensure clients have a thorough understanding of deliverables and are able to answer questions from Notified Bodies and the FDA moving forward.

TYPICAL PROJECT PHASE 1

Support for BRAs & Definition of Test Plan

Our biocompatibility team consistently performs BRAs for medical devices according to the ISO 10993-1 compliant process and template. We provide detailed risk assessments, including the evaluation of device raw materials, packaging, manufacturing process and adjuvants. We evaluate the biological risks associated with the degradation of the device during its whole life cycle, including storage and use. This risk analysis then leads to the definition of test plans.

TYPICAL PROJECT PHASE 2

Support to Interact with Test Laboratories

For non-experts, ensuring the test laboratory performs the desired tests using the appropriate conditions can sometimes be complicated. To avoid the unnecessary costs and delay of having to repeat testing, the Veranex team can act as independent intermediary and review quotations, test protocols and reports.

TYPICAL PROJECT PHASE 3

Analysis of Test Results and Biological Safety Conclusion

Once tests have been conducted, analysis is needed to determine whether the device can be considered safe or if additional tests are necessary. Depending on the testing performed, the analysis may include the performance of Toxicological Risk Assessments (TRAs) according to ISO 10993-17.

OTHER TYPICAL ACTIVITIES

Review of SOP & Template, Staff Training

Veranex reviews the client’s SOP and BRA template to bring them into alignment with Notified Bodies’ expectations. We also provide in-depth training so that the client understands why we conducted a highly detailed evaluation.

Our biocompatibility team consistently performs BRAs for various devices according to the newly developed templates. We provide detailed risk assessments, update test plans, and analyze test results while being consistent between all BRAs to generate ISO 10993-1 compliant reports.

Support from Development to Market Access

We provide support to our clients from the early development stages of their medical device, with initial risk analyses and help with material selection, all the way to the review of their technical documentation by Notified Bodies and the FDA. The key to success is to continuously learn from past projects and implement improvements in subsequent projects.

Your Guide to Biocompatibility Success

Through continuous collaboration with each client including regular meetings, open discussions, and consistent feedback both ways, we work in close partnership with clients to assess the biological safety of various devices, including large portfolios of dental products, dressings, intravenous catheters, brain electrodes, heart valves, eye implants, substance-based medical devices, surgical tools and robots.

Following our strategic approach, our clients’ devices have gone through CE certification in Europe as well as FDA review in the US and are now compliant with the latest regulations, allowing them to remain or be made available on the EU and US markets.

The key to success for Veranex is to assemble a team of scientific experts that are able to react and provide customized support, in a quick and efficient manner.