Anyone who works in medtech product development knows that surprises are a guarantee. That’s why it’s important to create stability and predictability whenever possible — especially when it comes to supply chain. Below, experts from our manufacturing team lay out four supply chain issues that they’ve encountered frequently in their careers and how Veranex prevents and solves them.

Problem #1

It’s easy to over-design a product without consideration for material availability, cost, and the supply chain that goes with it. Nothing’s worse than finding out later on in the manufacturing process that the cost is prohibitively high or a certain part is too expensive to manufacture.

Our Solution

We have the in-house expertise and capability to invest in early-design work. Our designers work closely with our supply chain team to assess material availability, location, and cost. This gives our clients a higher likelihood of developing a lower-cost product that doesn’t sacrifice functionality.

Problem #2

Not every supplier is going to be able to support a company as it moves through the commercialization process. And plenty of manufacturers can make something once, but struggle to produce at scale without producing a bunch of scrap and while maintaining a traceable process. Picking the wrong supplier and manufacturer can set you up for failure if they’re not able to support you long-term.

Our Solution

We address this problem by leveraging our approved vendor list (AVL), which is made up of suppliers that we’ve built strong relationships with and assess regularly for supply chain risk. We present the client with a selection of suppliers and partners that are able to take an early plan to automated production at high volumes. We want to make sure every client uses highly qualified suppliers for the job, with traceable processes.

Problem #3

Not all ISO1345-organizations are alike, with some lacking maturity in their processes. For example, we’ve worked with a client that, months after acquiring a company, while working toward a regulatory audit, realized the company does not have a healthy supply chain or robust material control plan.

Our Solution

Our team can go on-site, understand their current needs and quality requirements then develop internal supply chain and logistics strategies, assist in executing that plan, and put into place the approriate material flows and controls. We can utilize the organization’s systems and train their employees to the same standard.

Problem #4

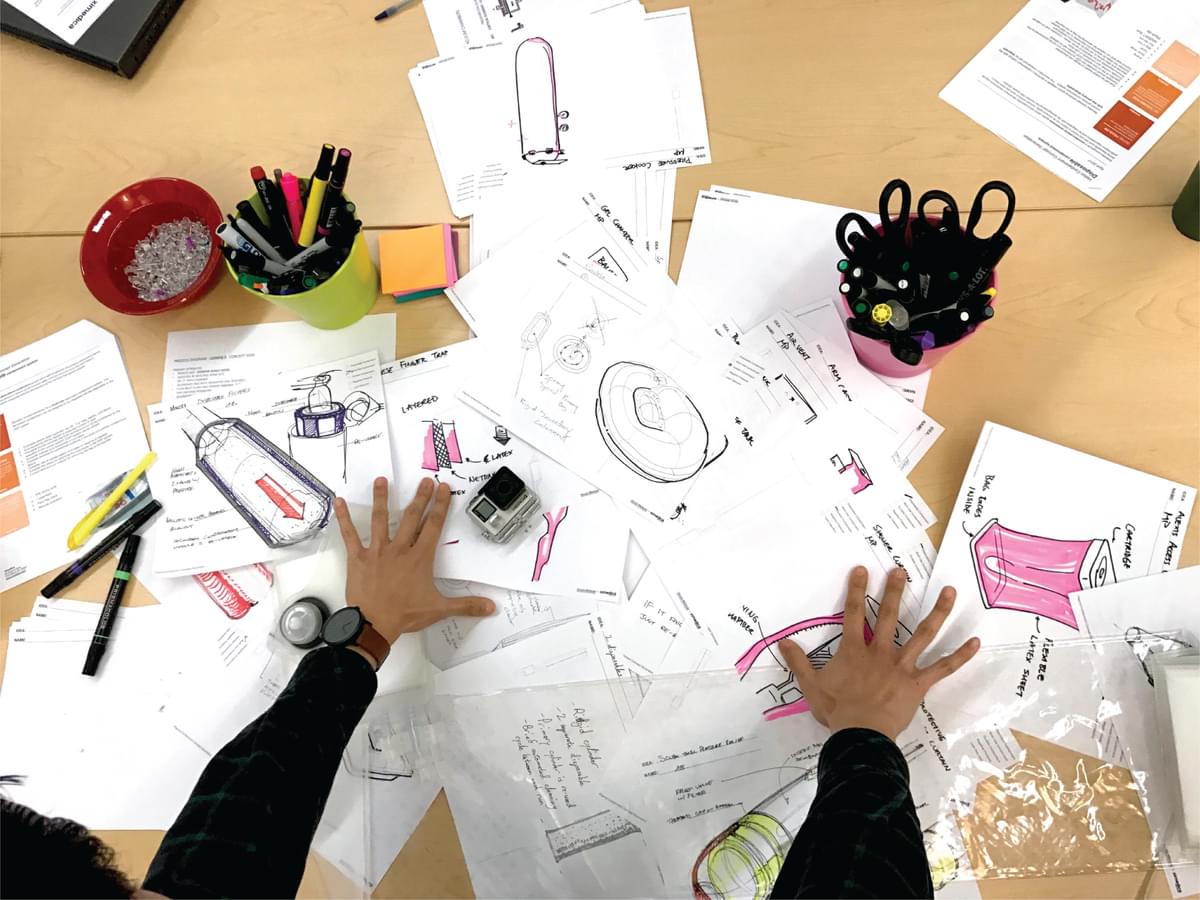

Clients frequently need quick-turn iterations — in weeks, not months — in the early prototyping and design world.

Our Solution

Our supplier relationships and past experience enables us to leverage our expertise and agility to get custom needs turned quickly and at an early phase.

What Does Supply Chain Mean in the Medical Device Industry?

Our approach to supply chain management is centered around creating and maintaining stability and continuity. With the risk of interruption to supply, inconsistent quality, and cost pressure, having a stable supply chain for your device is critical for establishing and growing your product, and your business.

Our AVL, which is based on business reviews, risk-based audits, and close working relationships, allows us to stay ahead of change, optimize inventory management, develop contingency plans, and use traceable components that meet quality standards, improving efficiency for you as your product gets closer to realization.