← REGULATORY AFFAIRS & QUALITY MANAGEMENT

Design & Manufacturing

Quality Engineering

Designing and manufacturing a medical device requires a systematic approach that accounts for risk assessment, regulatory requirements, and quality control procedures. Veranex’s expertise and commitment to excellence ensure a smooth and efficient process, enabling you to achieve your goals.

Risk Management

Risk management is a crucial process that involves identifying potential hazards, evaluating their potential impact, and implementing measures to mitigate the risks through design and process controls. A thorough and effective risk management process is crucial to ensure the safety and compliance of your device.

Our experienced consultants work closely with your team during this process to develop and implement a risk management plan that is both effective and aligned with all applicable regulations and standards.

By partnering with Veranex, you can be assured that your risk management process will be optimized to improve the safety and performance of your device, ultimately benefiting patients and users.

Design and Manufacturing Control

Design and manufacturing controls must be carefully considered together to ensure the safety and effectiveness of the device for its intended use.

We work closely with your team to develop a solid design and manufacturing plan that considers all aspects of the project, including resources, timelines, and milestones, as well as quality requirements such as inspections, testing, and documentation. Our team brings deep expertise in design and manufacturing controls and a proven track record of success, helping you to bring your product to market quickly and with confidence.

Design Implementation

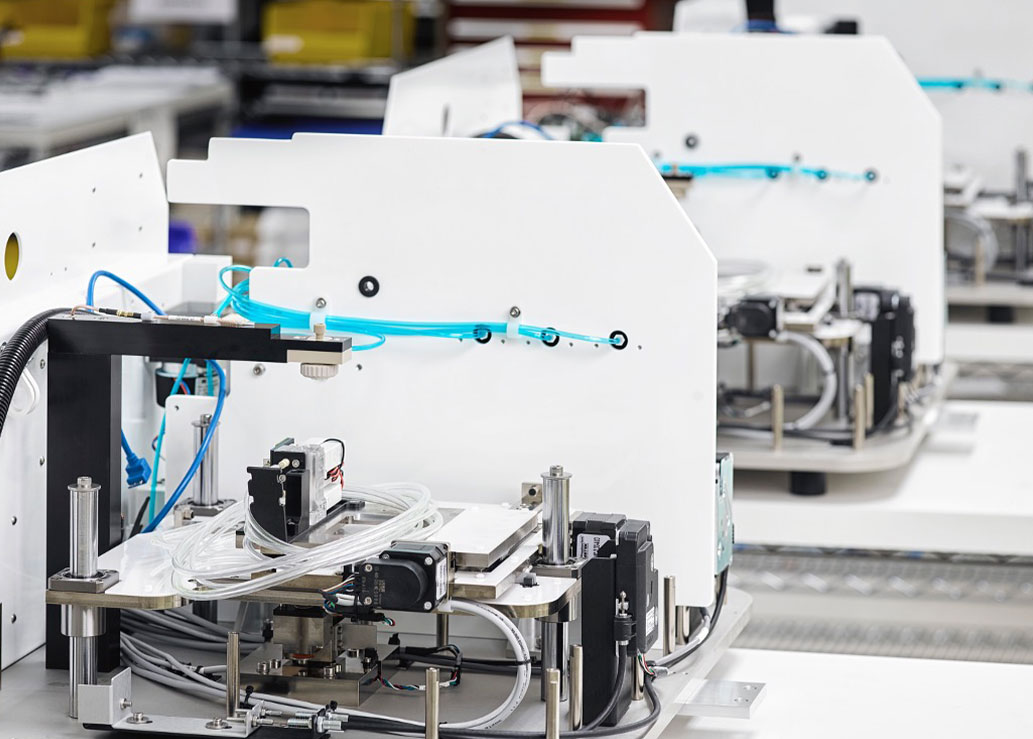

Transforming a design concept into a physical product that meets all quality, safety, and regulatory requirements is one of the more challenging aspects of commercializing a medical device.

At Veranex, we provide customized testing and validation strategies for design implementation to ensure your medical device meets all relevant regulatory requirements and industry standards. Our team of quality experts and product development engineers are well versed in expediting technological development for commercial success. Visit our Product Development & Engineering page to find out more on how we accelerate the realization of your products and deliver meaningful outcomes for patients and healthcare practitioners.

How does it feel to work with the Veranex Design Manufacturing and Quality Engineering Team?

Seamless collaboration between different areas is critical for the successful production of a compliant medical device. Our experienced team will work closely with your group, providing guidance, oversight, and review to ensure your device meets all necessary regulations and standards.

Our approach includes advising on regulatory requirements and standards, conducting risk assessments, creating or reviewing your design specifications, testing plans, and manufacturing control procedures, and providing feedback to improve the efficiency of the design and manufacturing process.

Design Manufacturing & Quality Engineering Services & Capabilities:

Risk Management

- Risk management support

- Product risk assessment and post-market surveillance

- Process hazard analysis and risk control

Design and Manufacturing Control

- Design control support

- Design history file (DHF) assessment/management and documentation support

- Manufacturing process development, validation, and process improvement

- Facility design, maintenance, and transfer support

Design Implementation

- Project management support

- Technical support for product testing (performance, electrical and mechanical safety, transit/packaging, sterilization, cleaning, disinfection, biocompatibility, human factors/usability, software and firmware, cybersecurity, products derived from tissues of animal origin)

- Process validation and revalidation, including controlled environment and clean room commissioning support

- Training

- Verification and validation (V&V) master plans, testing execution, and test report creation