Advance Your Medical Device Design with Confidence

Gain clarity and confidence in your product design with our expert human-centered approach and effective design iteration capabilities.

Driving Medical Device Design Success

Discover how our tailored services bring this powerful combination of insight, process, and expertise to your project.

Embark on your medical device design journey with a partner who places user needs at the heart of every innovation. Our proven, human-centered approach ensures we uncover critical insights that drive impactful solutions.

Our integrated teams of seasoned medical device design disciplines of industrial design, UX/UI, engineers, and strategists will guide you through complex challenges. Together, we navigate the path from initial concept to tangible results, leveraging best practices to de-risk development and accelerate your success.

Our expert teams initiate your medical device design by deeply understanding your commercial goals and the user's context of use, uncovering unmet needs to craft a patient-centric product strategy. Leveraging these insights and enabling technologies within our dynamic, iterative process, we collaboratively identify technical risks and forge a compelling, executable concept direction designed to meet your business objectives and deliver market-leading medical devices.

Strategic Deliverables:

- Product Roadmaps

- Generational Planning

- Business Drivers

- Information Architecture

- Product Concept Solutions

- Wireframes

Engage directly with our cross-functional subject matter experts and human-centered industrial designers in facilitated co-creation sessions designed to capture a successful future product pathway for your medical device design. At your site or ours, our integrated team guides you through a dynamic, collaborative process, ensuring we collectively review insights and achieve informed concept directions aligned with your business goals and focused on commercial success.

Transform your medical device design concepts into tangible prototypes within our integrated labs, enabling rapid iterations fueled by our dynamic design process. Our research, usability, and engineering experts collaborate to evaluate the prototypes, conducting concept feedback studies to uncover deep user insights and ensure an intuitive user experience. This iterative learning de-risks features and refines the design, moving you efficiently towards medical device proof of concept and commercial success.

Achieve critical medical device proof of concept as our expert, cross-functional teams address core technical problems and key anatomical mechanisms. Through our best-practice iterative process, we rapidly generate concepts and develop functional prototypes, gathering data to demonstrate your medical device design’s core feasibility. This evaluation process de-risks your innovation and achieves a significant milestone with evidenced-backed confidence to aid in securing future investment and support for continued development.

We construct intuitive digital experiences by considering your visual brand, clinical information & user interaction to design detailed components of your digital product. These design files are packaged for supporting your software development needs with our internal SW teams or yours.

Our human-centered design experts construct intuitive digital experiences by considering your visual brand, critical clinical information, and a deep understanding of user interaction. Following our iterative design process, our integrated team of UX/UI designers and engineers meticulously design detailed components. We then package these medical device design files to seamlessly support your software development, whether with our internal software teams or yours, ensuring the final product delivers a market-leading user experience.

Deliverables:

- Visual design direction

- UI Design product

- Digital prototype

- Component library & style guide

Effective labeling enables better comprehension and usability of your products for your regulatory submission and eventual launch. Our experience in carefully considering use steps informed by risk management activities allows us to mitigate through use step illustrations, instructional copy, information hierarchy, and layout for intuitive comprehension. Helping you increase safety and mitigate risk we have a proven process that successfully minimizes use error and helps the product’s regulatory pathway.

Usability and regulatory success for your medical device design requires effective labeling. With our proven human-centered design process, our experienced team carefully considers risk with each use steps and how labeling design can assist. We meticulously craft intuitive instructional copy, clear use-step illustrations, and logical information hierarchies to enhance comprehension, increase safety, and mitigate use error, ultimately supporting a smooth regulatory pathway for your market-leading medical device

Areas of Support

- Instruction for use (IFU)

- Quick Reference Guides (QRG)

- Packaging Artwork

- On Device Labeling

- Iconography

Applied Science Driven Medical Device Design

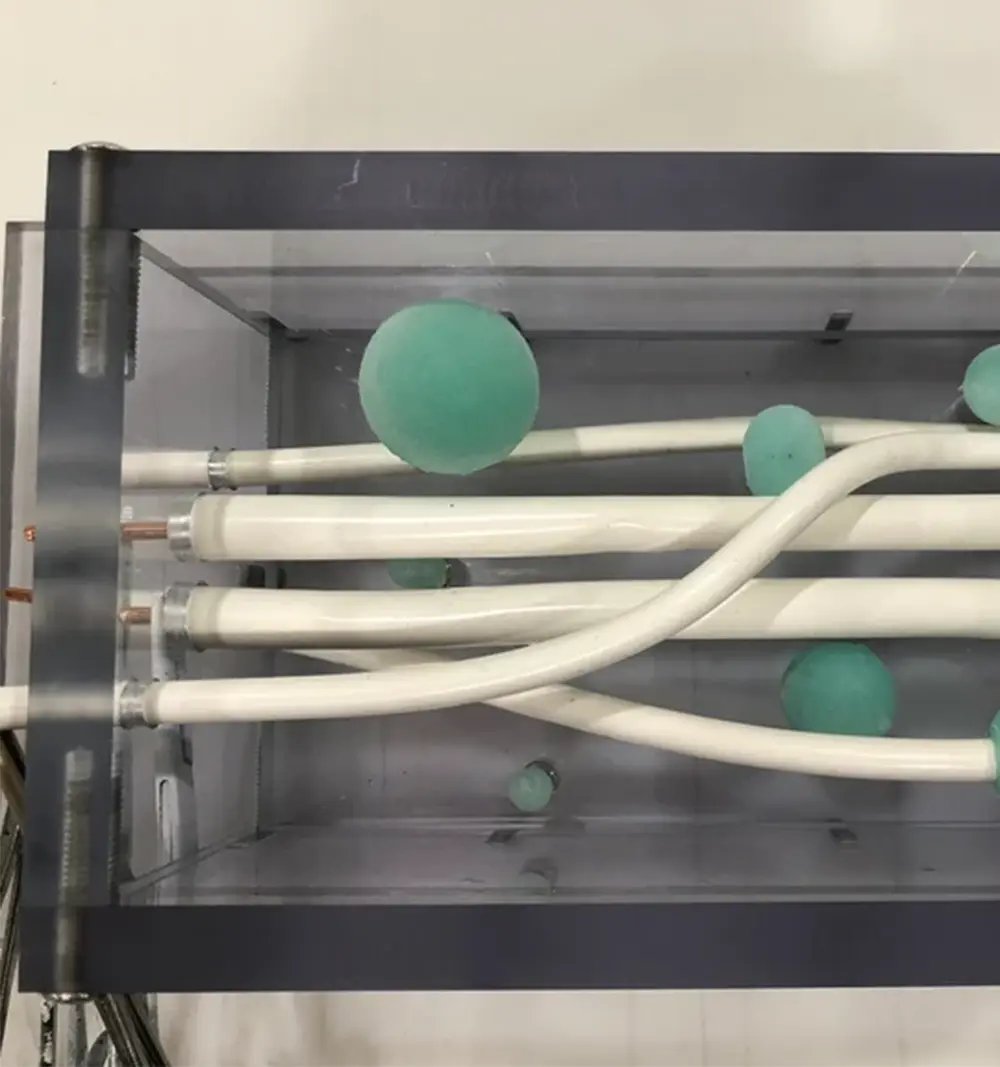

Refine your medical device design with our applied science expertise, ensuring proof of concept assessments are authentically representative of anatomy and real-world environments to ensure you design can meet functional demands. We combine deep physiological characterization with Design of Experiments (DOE) methodologies, leveraging advanced benchtop testing using animal/human tissues or blood (handled in our BSL I/II labs), and physiologically accurate surrogate models.

Areas of expertise:

- Microfluidics

- Optics

- Sensing Systems

- Artificial Tissue

- Advanced Analytics

Related Articles

Latest Blog Entries Related to Medical Device Design

6 min read

Strengthen Medical Device Development with a Well-Defined Design Feasibility Gate

Joe Gordon:

Case Studies

Real-World Impacts from Our Medical Device Design Services

Improved Usability Design Definition

Situation

Veranex was tasked with rapidly redesigning a urethral injection system interface for SUI treatment, addressing significant usability concerns from a previous design to achieve a functional proof of concept.

Successes

- Delivered two refined concepts, a detailed prototype design, and final functional prototypes with preliminary biocompatibility analysis, all within a 12-week timeline.

- Successfully redefined the injection scheme and developed a new device interface with precise urethral length adjustment and an intuitive adjustment feature.

- Engineered critical safety interlocks for needle deployment, preventing movement if not correctly positioned and ensuring injections occur at a safe distance from the bladder.

Services by Veranex

- Design Engineering

- Industrial engineering

- Prototype capabilities

- Biocompatibility testing services

- Suply chain and procurement services

COG Reduction Design Strategy

Situation

Client partnered with Veranex to support a redesign of their women’s health hemorrhaging device to reduce COGs and allow them to distribute to lower income markets.

Successes

- Initial alignment through criteria definition and prioritization showed the design team the top considerations for the design’s were speed to market and reduction of COGs.

- The concept down-selection workshop resulted in 2 system concepts that shared similar components to reduce COGs, ease of manufacturing, and streamlined a development pathway to get to both systems to market faster.

- In house silicone 3D printing capabilities, allowed the team to quickly iterate and assess designs to deliver proof of concept data 4 weeks ahead of schedule.

Services by Veranex

- Industrial Design

- Design and Mechanical Engineering

- Prototype and Shop

- Research & Strategy

Surgery System Design and Development

Situation

The client needed support envisioning and designing the next Endoscopic Cyclophotocoagulation (ECP) surgery system.

Successes

- Insights informed key design focus areas, driving the creation of 191 individual conceptual elements for 3 system concept directions then into down-selection

- Iterative testing, evaluation, and refinement of early prototypes resulted in generation of 2 volumetric system prototypes to refine the design and successfully integrated critical features, addressed key workflow challenges and mitigated use errors.

- The resulting design completed development and is now setting a new standard in the market for glaucoma treatment.

Services by Veranex

- Research and Strategy

- Industrial Design

- Human Factors

- UX / UI Design

- Engineering

- Design Assurance

Meet the Team

The Experts that Translate User Insights into Product Solutions

Our skilled teams utilize a human-centered approach to medical device design that transforms your vision into market-leading products, ensuring usability, mitigating risks, and accelerating your commercial success.

David Copeland

Sr Principal, Human Centered- Industrial Designer

Bringing almost 30 years of product development experience across a broad array of categories and markets, David manages cross-functional teams to deliver compelling solutions. He leads and advises a multidisciplined team comprised of industrial designers, user interface experts, and usability specialists. David and his team are user advocates, working to collect and uncover all apparent and unmet needs a user may have while using a product. He and his team then work to integrate enhancements into a solution that resolve the identified problem, ensuring the device’s function fits the users’ needs.

David contributes and collaborates on programs, within both healthcare and diagnostics markets, developing strategies to execute on our clients’ goals and leads early phase development activities to accomplish this. He is experienced in cardiac catheter navigation and delivery technologies, pulmonary diagnostics, wearable devices and monitors, point-of-care (POC) diagnostics, lab-based imaging technologies, and home health diagnostics and care.

Joe Gordon

VP, Innovation and Technology

Joe drives Veranex’s innovation process for our valued clients by identifying business strategies, opportunities, and new technologies that impact their core businesses whether it is solutions in medical devices, healthcare delivery, diagnostics and/or consumer healthcare products. He leads and advises cross-functional teams of experts, in collaboration with a global client base, to develop creative solutions for our most challenging and complex projects. Examples include the clean slate development of a digital surgical robotic system through traceable builds in just over 3 years.

Throughout his 20+ year career, quarterbacking over 300+ projects, Joe has been at the core of Veranex’s ability to develop breakthrough solutions and is nearly always involved in overseeing nascent technology development and full end-to-end MedTech product development programs. In most every case, Joe’s role is to guide through the chaos to bring clarity to innovation and to distill it into practical digestible concepts. Correspondingly, Joe is highly skilled in navigating the most crowded of patent landscapes while driving and building robust patent protection strategies for our clients.

Joe has seasoned a breadth and an uncommon depth of demonstrated expertise in developing commercialized solutions across a wide range of specialized healthcare fields. From complex capital systems, next-gen wearables, or integrated drug delivery product platforms, Joe is our valued expert that sets our innovation compass in the right direction.

Discover More

Related Services at Veranex

Testing and Prototyping

Accelerate your design iterations. Our integrated teams leverage accessible, expansive facilities for rapid prototyping, bringing concepts to life quickly.

Human Factors

Integrate usability and safety early. Our HF experts provide continuous input, ensuring designs are intuitive, reduce risk, and are ready for successful submission testing.

Research & Strategy

Ensure strategic alignment from the start. We work closely to integrate foundational insights, guiding design parameters for concepts aligned with your goals.

Quality Services

Build quality in from day one. Our integrated Quality teams provide early risk assessments, proactively addressing concerns to inform design and proof of concept parameters.

Advance Your Medical Device Design from Concept to Reality

Partner with our expert medical device design team to achieve a compelling proof of concept, de-risk your development, and accelerate your journey to market success.