Successful Design Verification Powered by Integrated Prototyping and Testing Expertise

Decades of expertise with prototyping and testing to de-risk development and accelerate your path to a successful submission.

A COMPELLING AND DEPLOYABLE SOLUTION

We treat prototyping and testing as a single function designed to generate verifiable proof, building a more robust device and a more defensible regulatory submission simultaneously. By co-locating our engineering, prototyping, and testing teams, we create a powerful engine of continuous improvement. Allowing us to build, test, analyze, and refine in days, not months, to generate robust data needed to support design verification activities at every stage.

A device is only as strong as the evidence that supports it.

Critical Prototype and Testing Capabilities for Successful Design Verification

Our seamless feedback loop between prototyping and testing provides the evidence you need to de-risk and streamline development.

We create the physical tools you need to answer critical questions. Whether for early-stage feasibility, human factors studies, or rigorous benchtop testing, we select the right method to create a medical device prototype that generates meaningful data.

Our in-house capabilities include:

Additive Manufacturing

FDM, SLA, and PolyJet technologies for rapid creation of complex geometries and multi-material models.

CNC Machining

Precision-machined components in a wide range of medical-grade plastics and metals.

Urethane and Silicone Casting

Ideal for producing small batches of production-quality parts for extensive testing or early evaluation.

Assembly and Finishing

Complete assembly, fit modification, and finishing services to create fully functional test models.

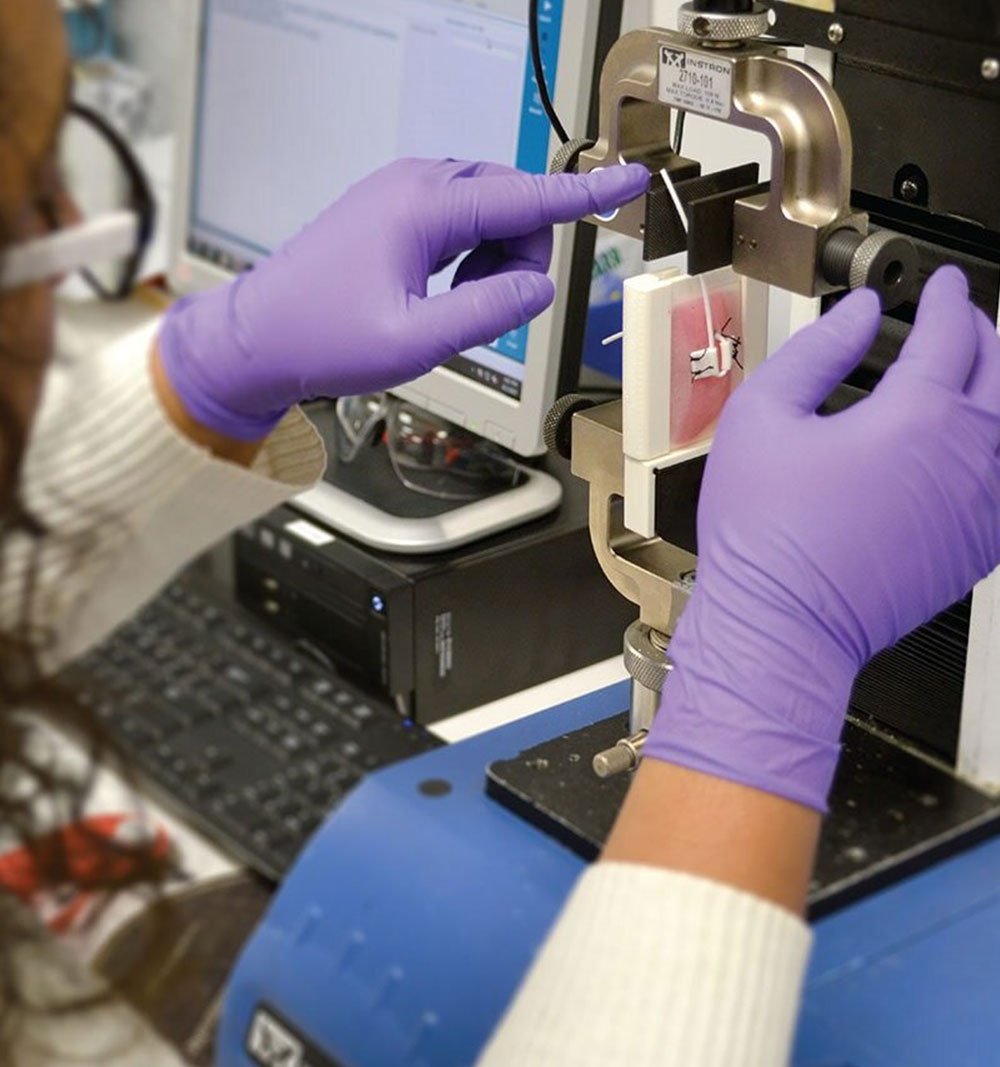

Rigorous Testing Services: Generating Evidence with Confidence

- Our ISO 13485-certified labs provide the data and documentation to prove your design performs as intended. We handle everything from standardized protocol execution to complex, custom analyses, ensuring the data is traceable, reliable, and submission ready.

- Ensure your device is reliable and market ready:

- Mechanical and Performance Testing:Characterizing performance under real-world physical forces

- Electrical Safety & Performance: Verification against IEC 60601 standards and other critical regulations.

- Environmental and Aging Simulation: Assessing device longevity and material durability.

- Packaging and Sterilization Validation: Ensuring sterile barrier integrity and robustness.

Custom Solutions for Design Verification Challenges

Standard tests are not always sufficient for trailblazing devices. Our expertise extends to developing and validating novel test methodologies to assess unique performance attributes or use cases.

Custom Test Fixture Design

We design and build custom fixtures and equipment to replicate clinical use and isolate critical performance variables.

Test Method Validation

We develop and execute robust test method validation protocols, providing the objective evidence required by regulatory bodies to prove that a novel test method is accurate, reliable, and fit for its intended purpose.

Anatomical Model Development

We research, develop, and validate physiologically accurate test models that authentically replicate the anatomical environment. These surrogates, often incorporating real tissue in our BSL-II labs, are robust enough for both rapid design iteration and formal design verification efforts.

Case Studies

Driving Testing and Prototyping Innovation & Strategy

Real applications where our team accelerated a device design to improve use, performance, and functionality through utilization of our testing and prototyping services.

Manufacturing Support

Situation

Inflammatix required a partner to industrialize their proof-of-concept system into a commercially viable diagnostic instrument, which included the design, development, and validation of manufacturing processes to support the production of units for a clinical study.

Successes

- The team successfully designed, developed, and validated the use of manufacturing fixtures that supported controlled in-process testing.

- Over 20 fully traceable instruments were built to support the needs of the projects clinical study that was critical for a successful regulatory submission.

- The manufacturing process, fixtures, and work instructions were strategically designed to support a seamless manufacturing transfer to a full production facility with minimal inefficiencies.

Services by Veranex

- Engineering and Development

- Prototyping and Shop

- Manufacturing Engineering

- Design Assurance Engineers

- Manufacturing Quality Engineers

- Testing Services

- Regulatory Consulting

Concept to Successful Launch

Situation

Improve ease of use by designing and developing a mechanical veinous thromboembolism device that leverages existing system accessories.

Successes

- 84% reduction in use errors from on-device and product labeling was demonstrated via a usability formative study with healthcare professionals.

- The Veranex team supported the handle, packaging, and labeling design and development along with sourcing the system accessories to combine into a final kit.

- Strategically optimized and compiling robust DHF for expedited 510(k) submission to be within 1 year from project kickoff.

Services by Veranex

- Early discovery

- Product design ideation

- Rapid prototyping and testing

- Human factors and usability testing

- Product design refinement

- Manufacturing

Accelerat Development with Iterative Prototype and Testing

Situation

A client's clinically effective and physician-preferred device was unprofitable due to high material costs and a tedious assembly process, necessitating a complete redesign for commercial viability.

Successes

- After defining critical parameters for clinical success and ease of use with the client and partner physicians, the team refined the concept for the redesigned device.

- The product design and prototype teams worked in close collaboration, rapidly iterating device variations with different silicone durometers and dimensions to gain stakeholder feedback based on tangible feel and maneuverability.

- In parallel with device refinement, the team developed and validated a physiologically accurate anatomical model, which was used to assess prototypes and conduct formal usability assessments.

Services by Veranex

- Research and Strategy

- Regulatory Consulting

- Design Engineering

- Testing and Prototyping

Discover More

Related Services at Veranex

Quality Services

Our quality experts ensure you perform the most critical testing by starting with a robust risk assessment. We then confirm your test methods are rigorously validated in accordance with regulatory standards, creating a clear and defensible path to submission approval.

Preclinical Services

Leverage our preclinical facilities and anatomical expertise to guide your test method development and refine your device design. Testing in a simulated clinical setting provides authentic, data-driven feedback, ensuring your device is optimized for real-world performance long before pivotal studies.

Engineering and Development

Our integrated engineering and development teams are central to your project’s success. We combine decades of experience with creative, solution-oriented strategies to solve complex challenges, ensuring your project navigates technical hurdles efficiently and reaches submission readiness faster.

Human Factors

From early usability models for formative studies to fully functional prototypes for validation, our teams provide the critical tools needed to guide user-centric design. We ensure your device is not only effective but also intuitive and safe for patients and clinicians.

De-Risk Your Path to Design Verification

Move from concept to certainty. Our integrated prototype and testing services and expertise will help de-risk development, satisfy regulatory requirements, and accelerate your timeline to being market ready.